Projects

Here are some of the projects we’ve delivered previously.

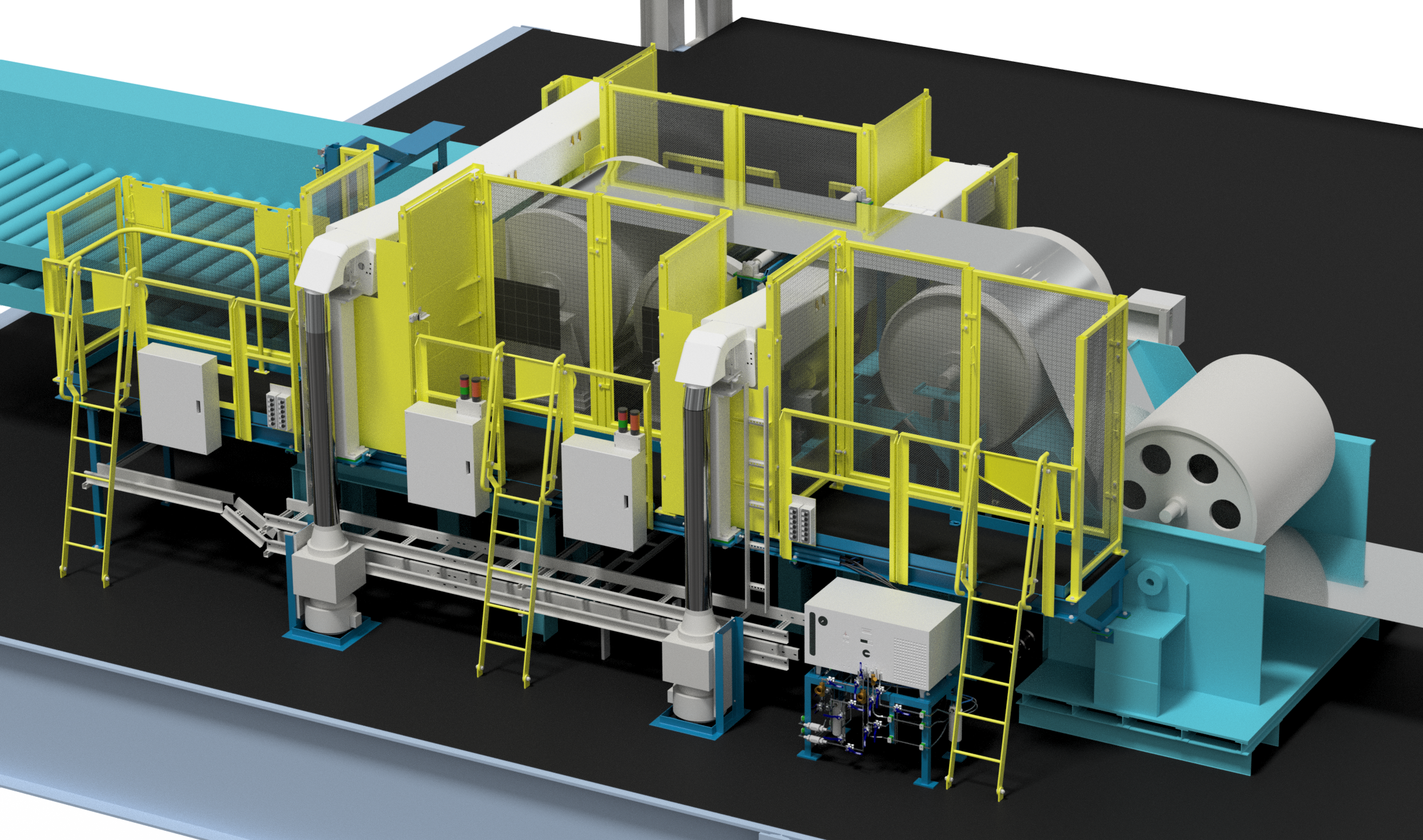

BlueScope Steel Metal Coating Line 7 (MCL7) Project - Western Sydney Service Centre

Project Overview

The BlueScope Steel Metal Coating Line Number 7 (MCL7) project at Erskine Park is an ongoing development aimed at enhancing Australia's steel manufacturing capabilities. With a planned processing capacity of 240,000 tonnes per annum, MCL7 is set to significantly impact the production of high-quality steel products for the construction, infrastructure, and housing sectors.

DesignX's Significant Role

DesignX is proud to serve as the lead supplier for 3D modelling and drafting services for this prestigious project. Our specialty services have been integral from the feasibility stages and continue to be crucial as the project progresses. Utilizing our deep industry knowledge of metal coating and processing lines, DesignX has ensured the effective integration of advanced 3D modelling technologies into the project's workflow.

Services Provided by DesignX

3D Modelling and CAD Management:

DesignX quickly assembled a team of highly skilled 3D designers who transformed the initial 2D plans into comprehensive 3D models. This transition has been pivotal in visualizing the project's feasibility and ensuring precise alignment with BlueScope's operational requirements.

Mechanical and Electrical Engineering:

As the project progresses, DesignX has expanded its service offerings to include both mechanical and electrical engineering. Our expertise in these areas is ensuring that all components of the metal coating line are designed and implemented to the highest standards of efficiency and safety.

Drone Mapping:

Our drone technology captures high-resolution aerial imagery and data, providing a comprehensive view of the project site. This invaluable data streamlines the design process, allowing for more informed decision-making. The aerial perspectives obtained through drone mapping enhance planning accuracy and project execution efficiency.

Project Impact

The MCL7 project, with its state-of-the-art facilities and advanced technology integration, underscores BlueScope's commitment to maintaining its leadership in the steel industry. DesignX's ongoing contributions are instrumental in realizing this vision, providing technical excellence and innovative solutions that set new benchmarks in the industry.

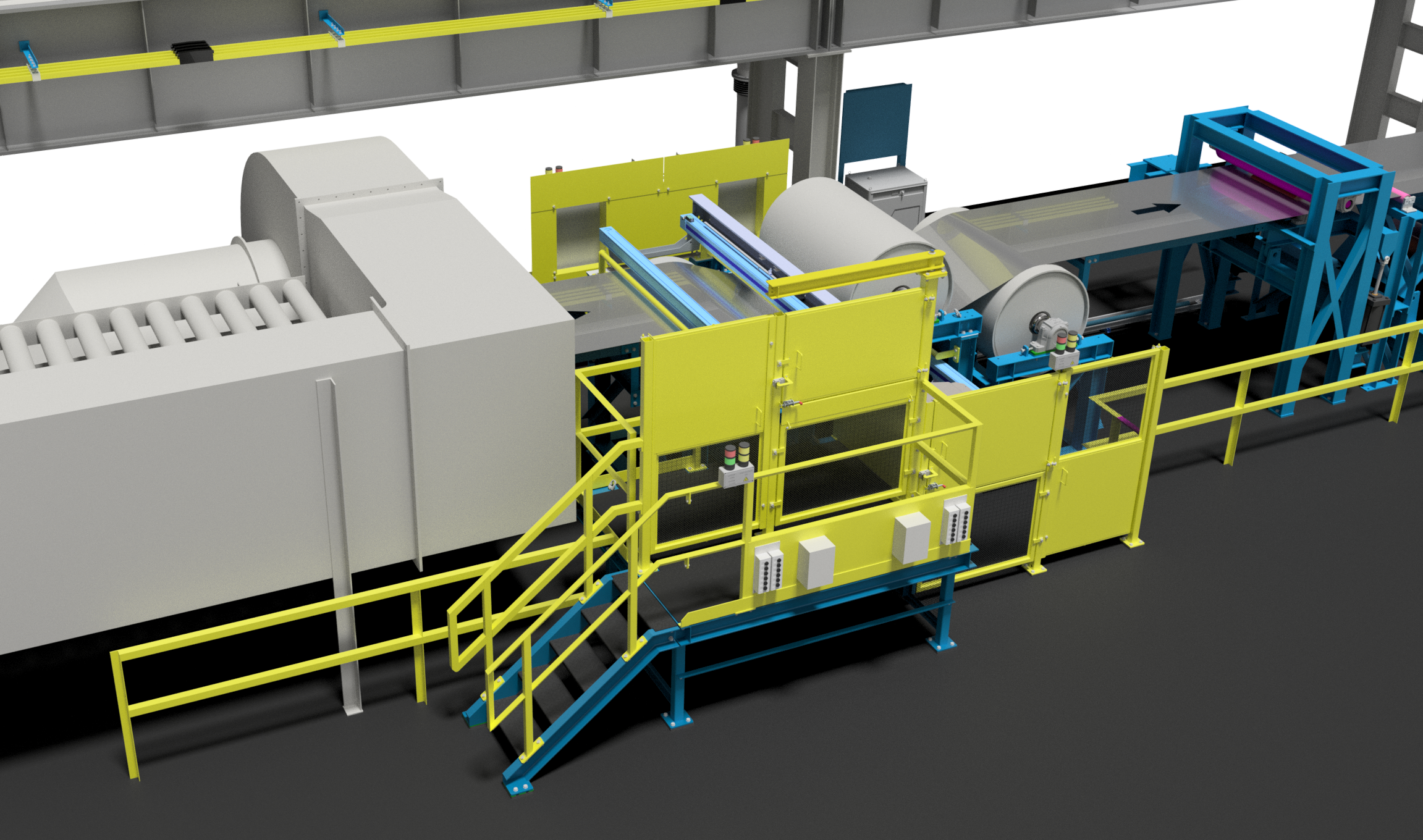

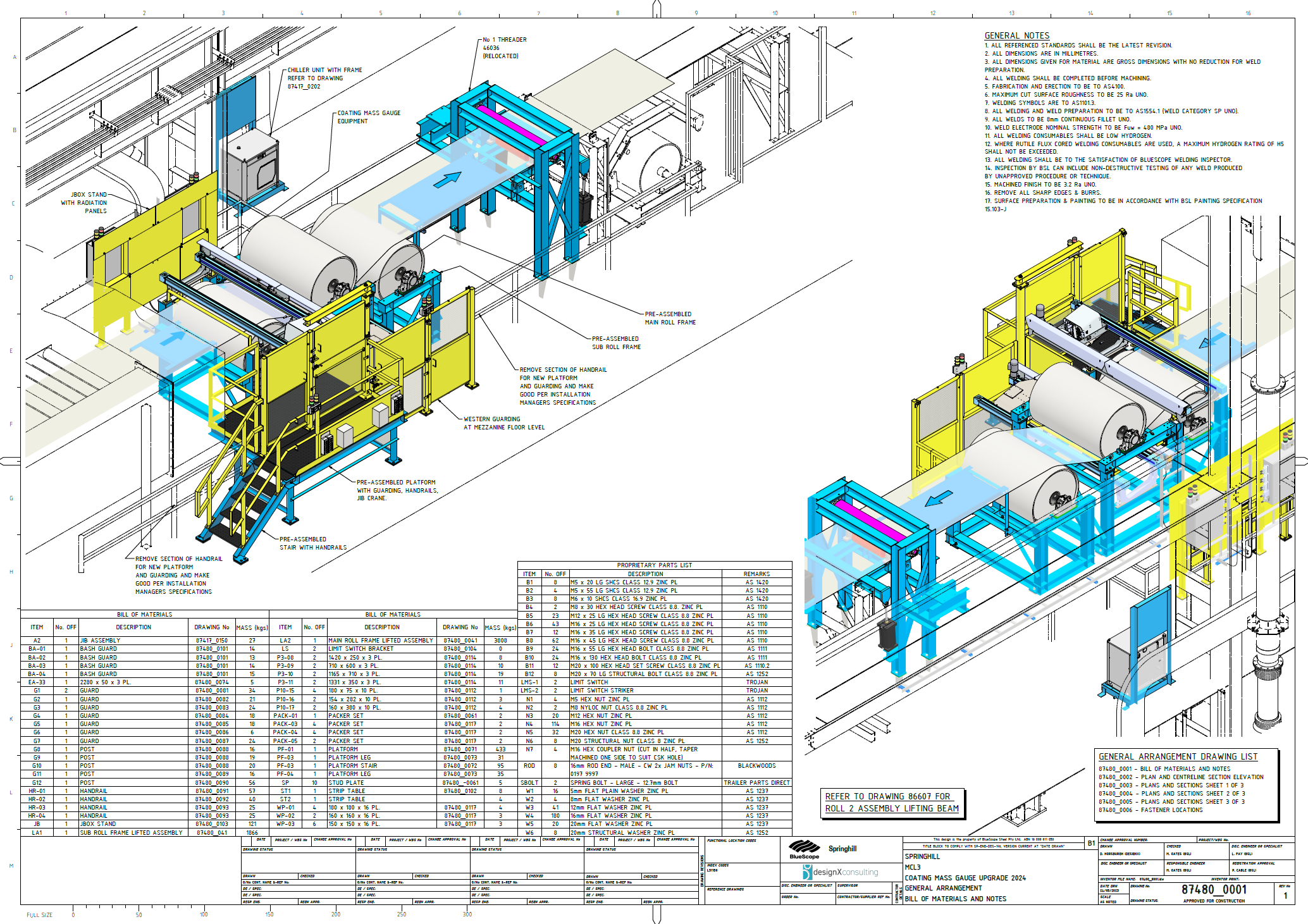

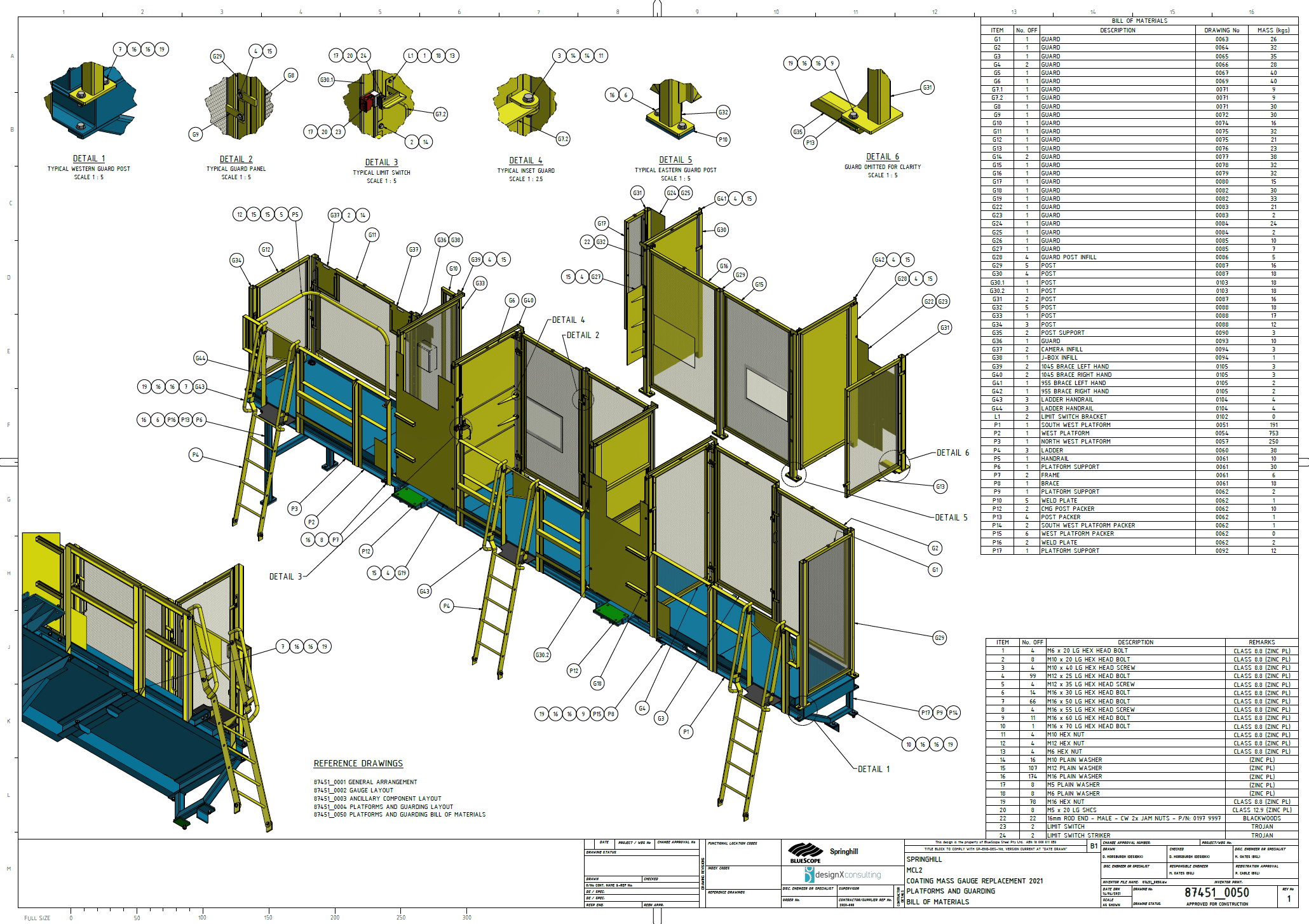

BlueScope Steel Coating Mass Gauge (CMG) Upgrades - Springhill Works

Project Overview

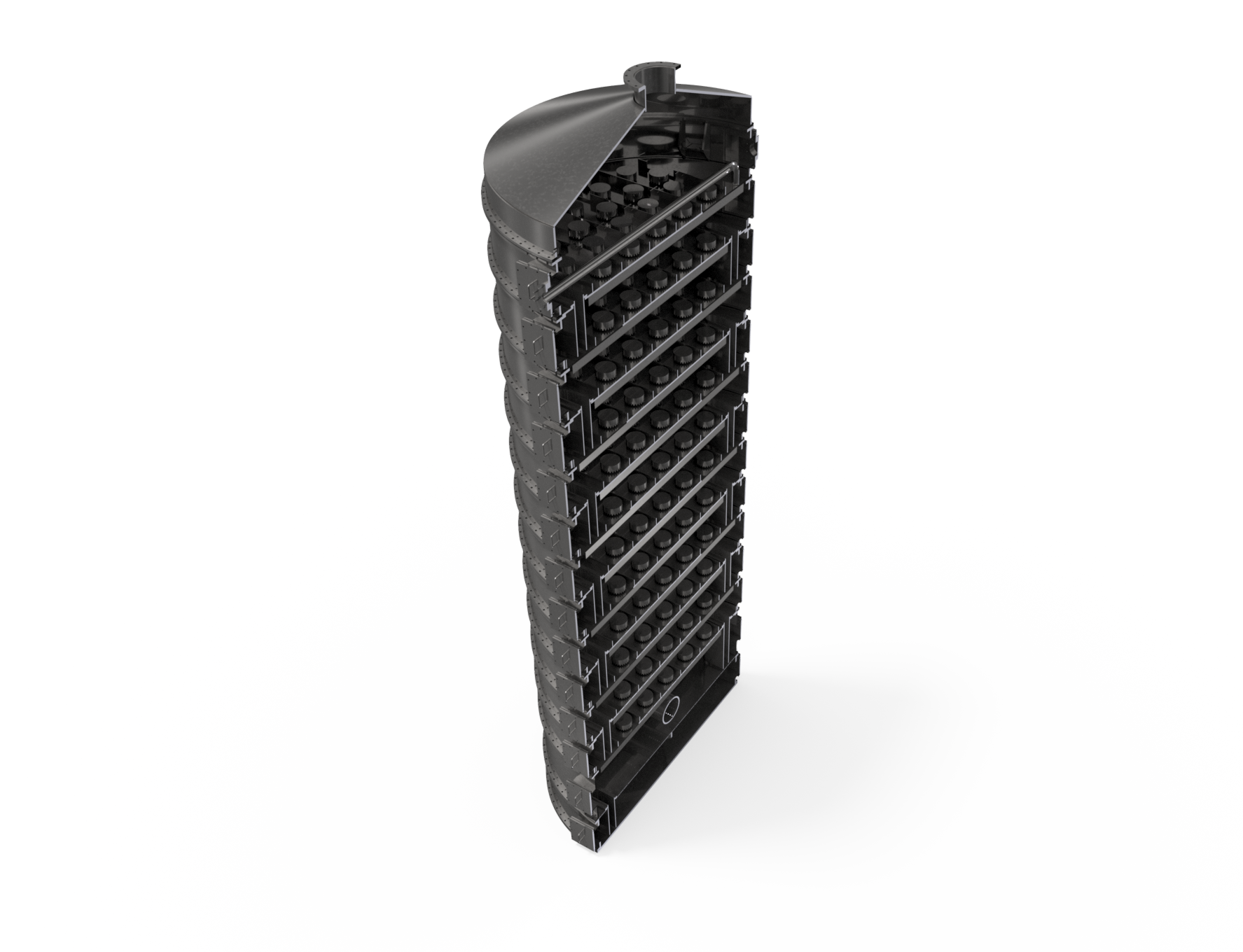

Our team successfully completed a series of critical upgrades to the Coating Mass Gauges (CMG) at BlueScope Steel's Springhill Works, involving the MCL1, MCL2, and MCL3 lines. This project aimed to modernize the existing systems with advanced X-ray technology, enhancing operational security and ensuring the economic viability of the metal coating lines.

Project Budget

MCL1: $1,400,000

MCL2: $1,200,000

MCL3: $1,900,000

Project Purpose

MCL1 & MCL3: Replacement of outdated 1970s isotope-type CMGs. The new equipment is strategically relocated closer to the hot metal pot to improve coating control efficiency.

MCL2: Upgrade of the 1980s X-ray type CMGs, with the new system installed in the original location due to space and operational constraints.

These upgrades were necessitated by the end-of-life status of the existing gauges, unavailability of spare parts, and the increasing difficulty in renewing operational licenses for the old technology.

Implementation Timeline

MCL2: Successfully installed and commissioned in August 2021, achieving a payback period of less than 2 years.

MCL1: Installation completed in November 2023, with operational readiness expected by August 2024.

MCL3: Installation currently underway, with completion and operational status anticipated by February 2025.

Engineering Feats

The design phase for MCL1 and MCL3 was meticulously planned to allow for a staggered installation, minimizing line downtime.

A total of 165 unique detailed drawings were created to guide the fabrication, installation, and future maintenance of the new systems.

Outcome

This project not only modernizes the technology at BlueScope Steel Springhill Works but also ensures compliance with current standards, reduces maintenance costs, and improves the precision of the coating process, thereby securing the facility's competitive edge in the steel industry.

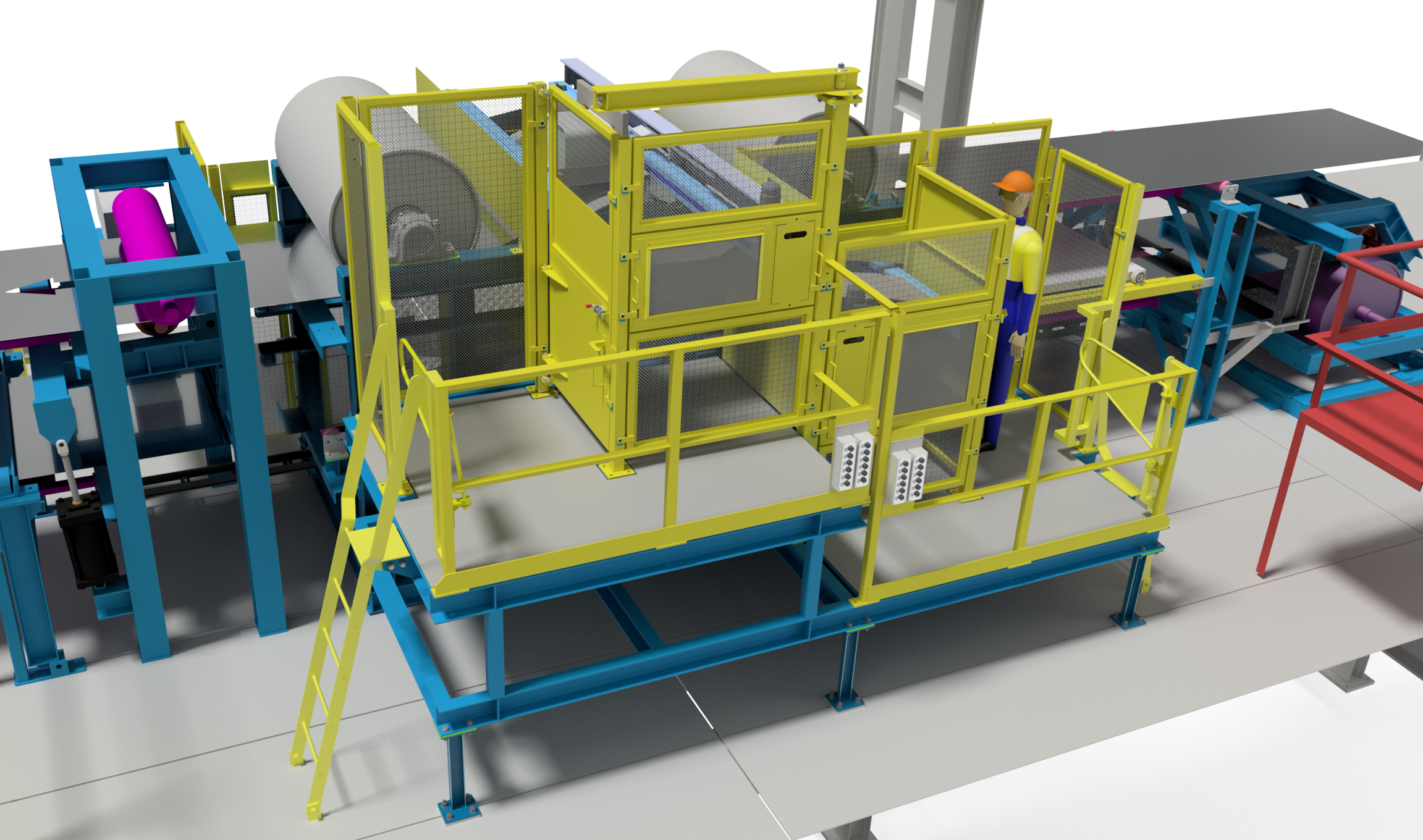

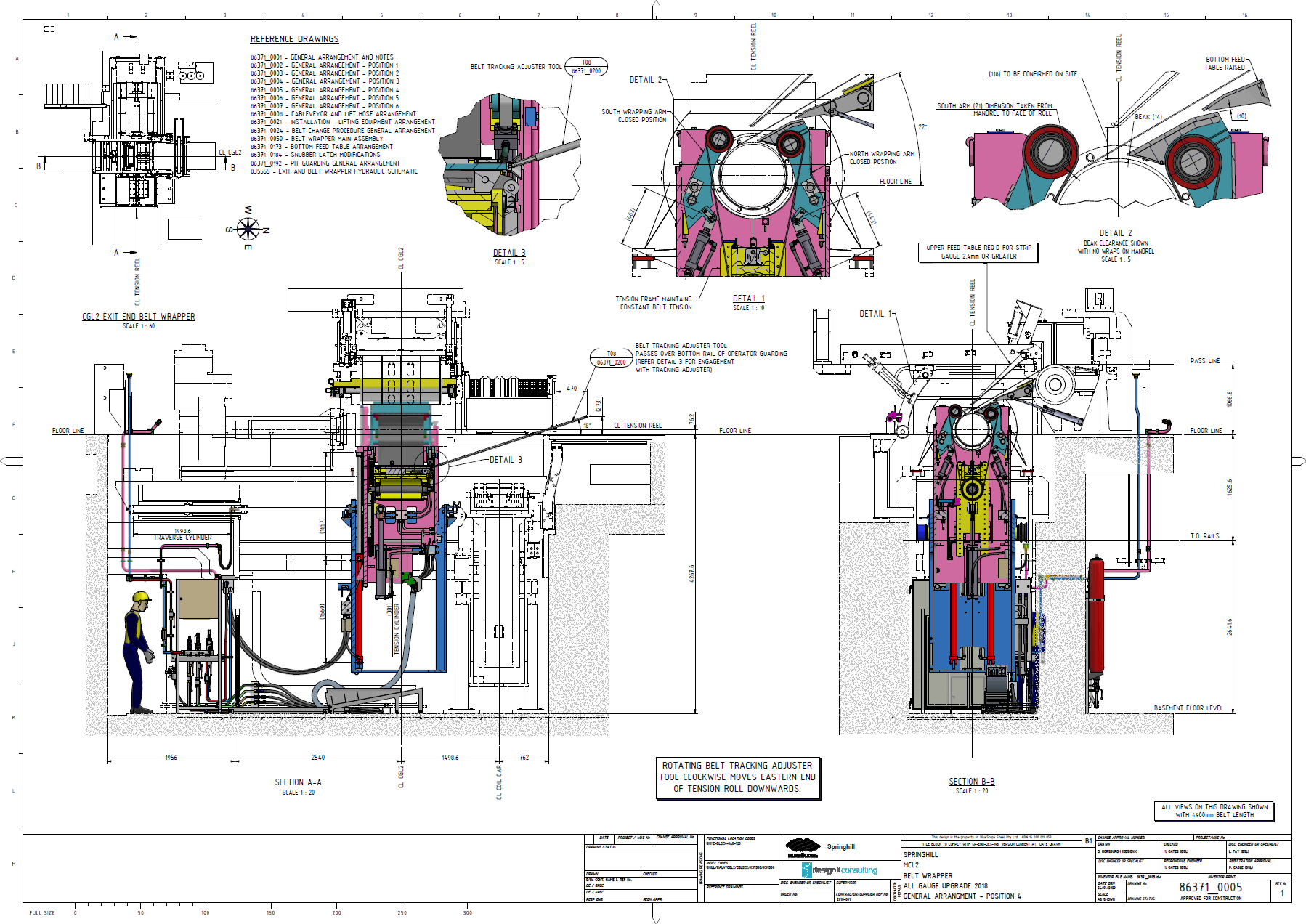

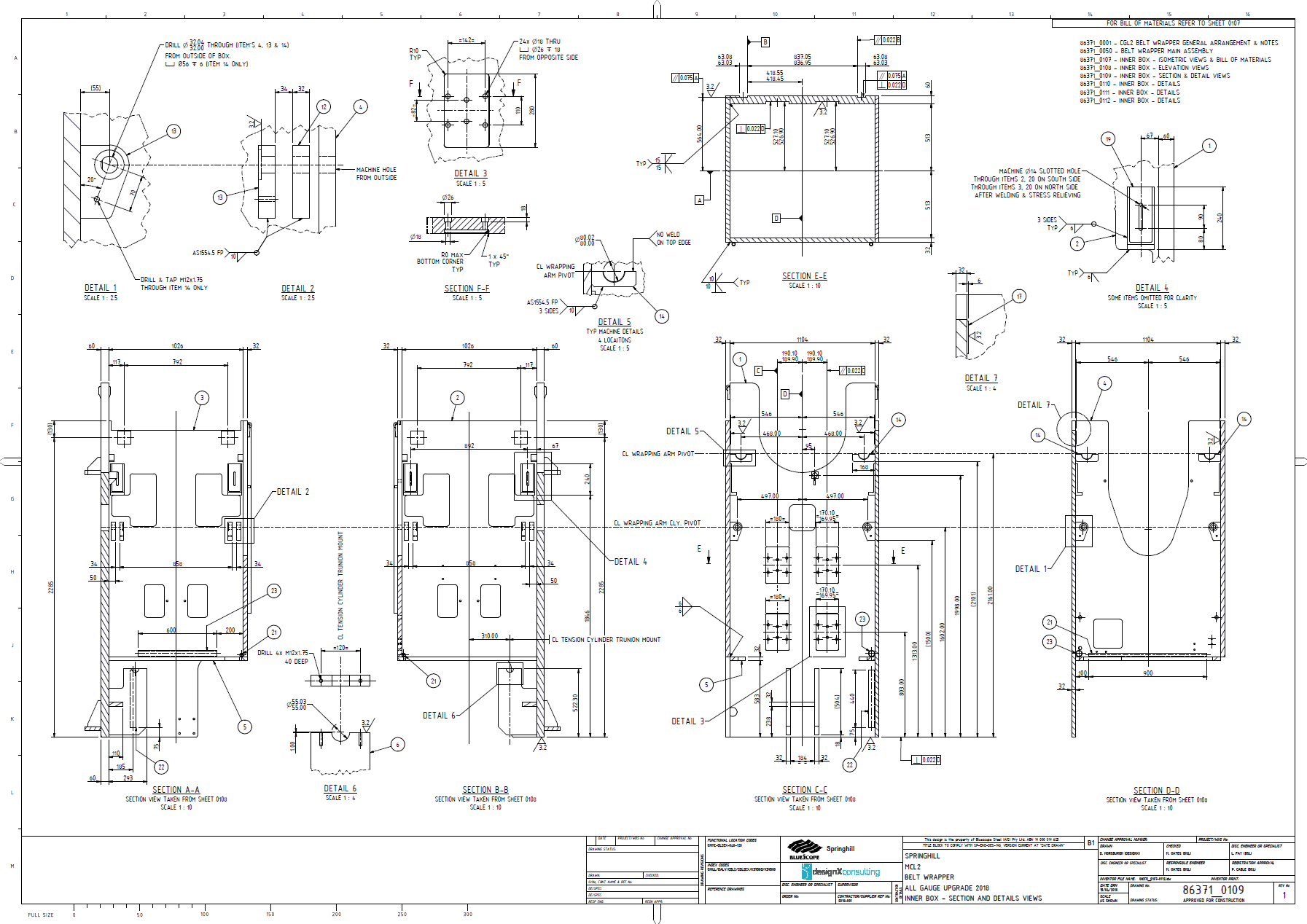

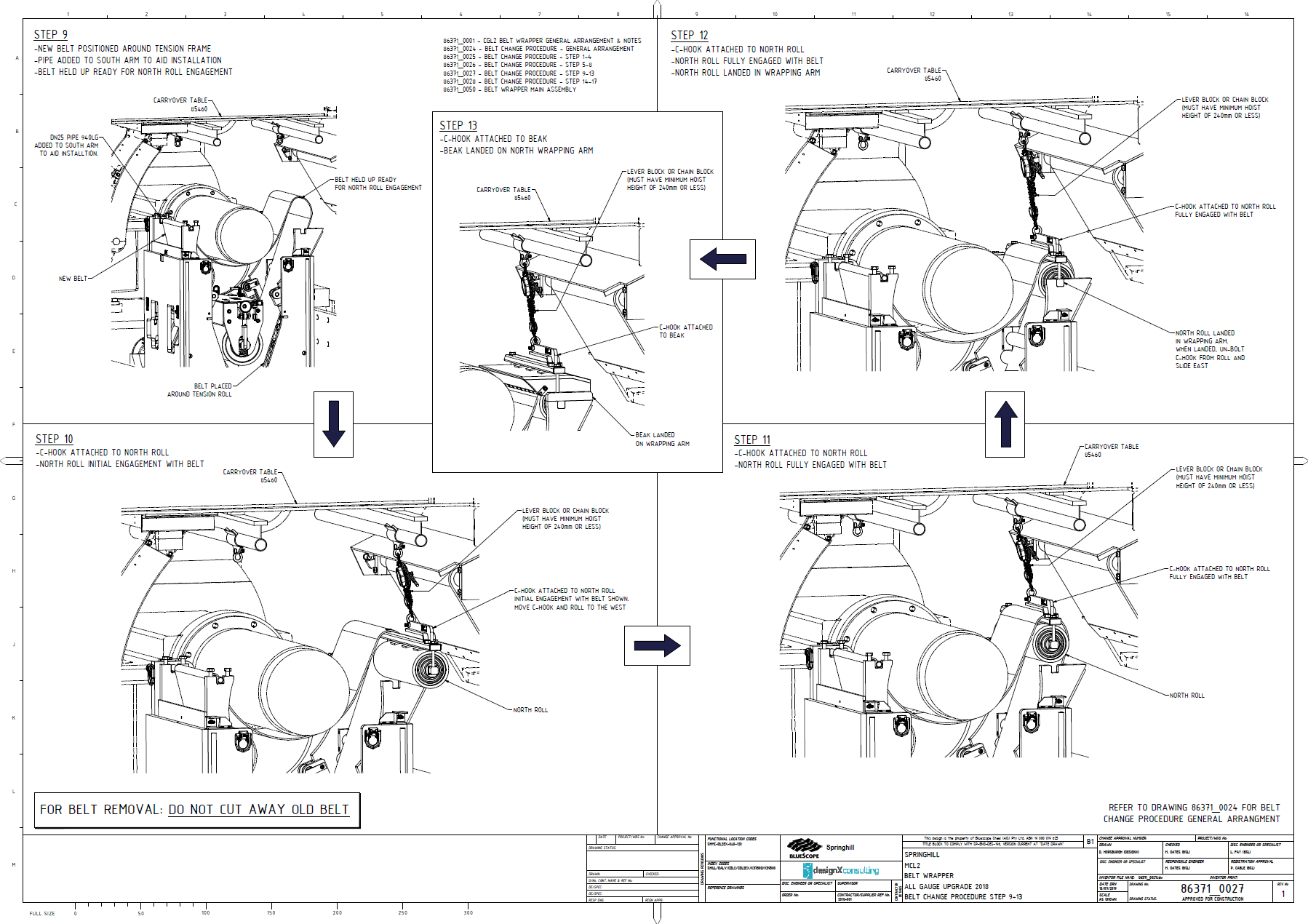

Bluescope Steel MCL Belt Wrapper Upgrade - Springhill Works

Project Overview

Our company undertook a significant upgrade project for the Metal Coating Line (MCL) Belt Wrapper at BlueScope Steel's Springhill Works. This project focused on replacing an antiquated 1960s design with a modern system capable of handling a broader range of product thicknesses, enhancing operational flexibility and efficiency.

Project Budget

Total Budget: $980,000

Project Purpose

The primary goal was to replace the outdated belt wrapper system, which had limitations in handling thicker steel strips, requiring the use of a gripper slot in the recoiler mandrel for products over 1.9mm thick.

The new system was designed to accommodate the complete product thickness range from 0.5mm to 3.5mm without the need for the gripper slot, thereby simplifying the process and reducing setup times.

Project Highlights

Increased Capability: The upgraded belt wrapper now efficiently processes the entire thickness range, improving production versatility and throughput.

Economic Efficiency: The project boasted a payback period of less than 2 years, showcasing its economic viability and the immediate benefits to production efficiency.

Implementation

Installation: The new belt wrapper was successfully installed and commissioned in November 2019, marking a swift transition to the upgraded technology with minimal disruption to ongoing operations.

Engineering and Design

Drawings: A comprehensive set of 165 unique detailed drawings were produced, ensuring precision in the fabrication, installation, and future maintenance of the new belt wrapper system.

Outcome

This upgrade has significantly enhanced the operational capabilities at BlueScope Steel Springhill Works, allowing for greater flexibility in product handling, reducing operational constraints, and contributing to the plant's overall productivity and competitiveness in the steel manufacturing sector.

Bluescope Steel Coil Field Expansion Project - Springhill Works

Project Overview

The Coil Field Expansion project at BlueScope Steel's Springhill Works was a strategic initiative aimed at optimizing the use of existing floor space across multiple buildings in Port Kembla. The primary objective was to enhance the on-site storage capacity for steel coils, thereby reducing the need for off-site storage and the associated logistics of double-handling.

Project Scope

Space Optimization: Utilization of available space to increase local storage, minimizing the need to transport coils off-site only to bring them back for further processing.

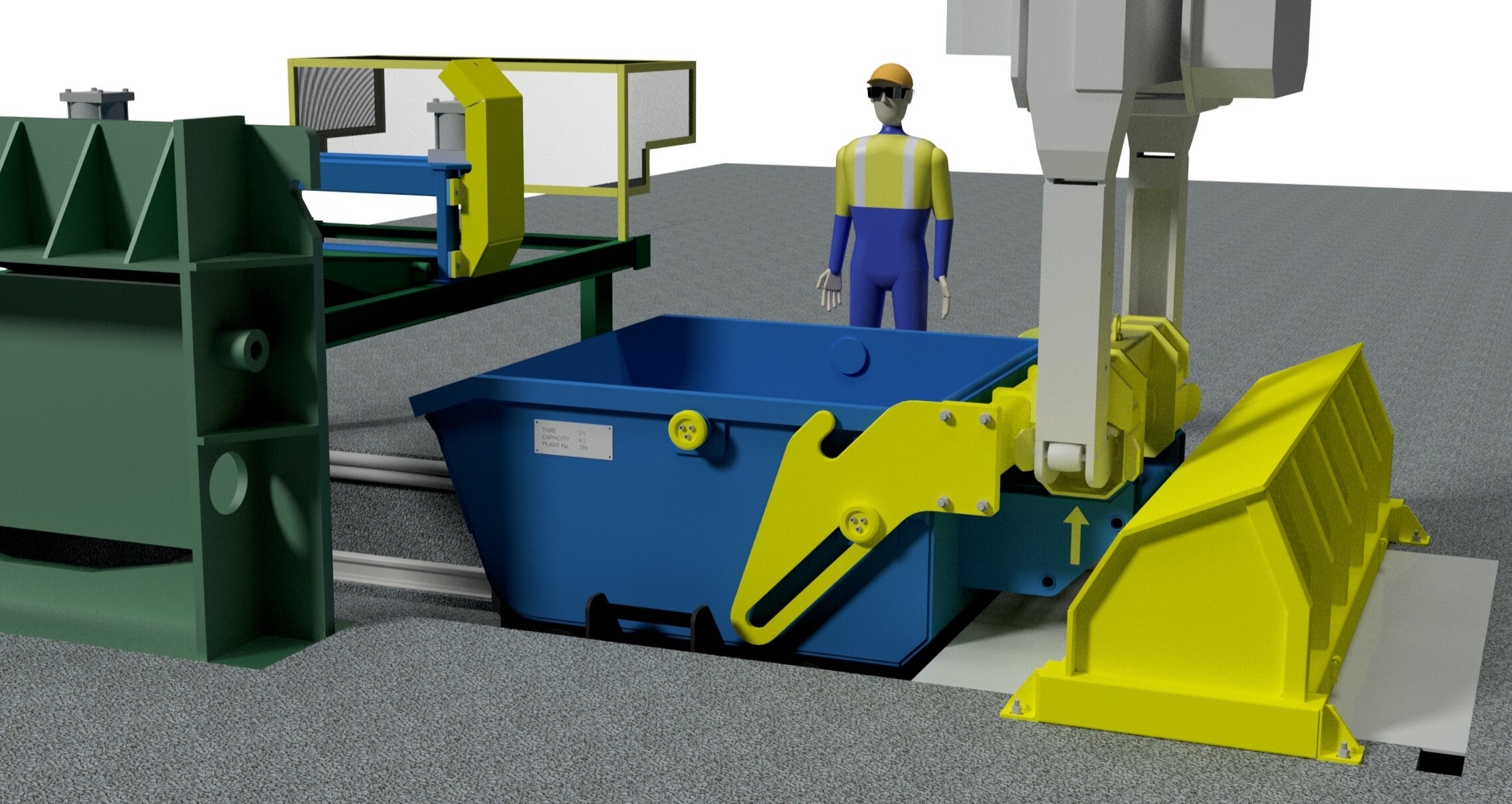

Engineering Design: DesignX contributed significantly by modeling existing structures and designing new elements including crane access platforms, anti-collision systems for cranes, self emptying steel scrap bins, and specialized lifting equipment.

Innovative Features

Automated Handling: Developed innovative solutions allowing scrap bins and lifting equipment to be managed via overhead cranes, thus eliminating manual handling. This design not only increased efficiency but also improved safety by reducing direct human interaction with heavy machinery.

Safety Enhancements: The new designs focused on reducing risk for both operators and crane drivers through automated and safer handling processes.

Project Outcomes

Capacity Increase: The project successfully added just under 600 additional coil storage positions, significantly enhancing the facility's storage capabilities.

Cost Efficiency: By avoiding the costs associated with off-site storage and transportation, the project has led to considerable annual cost savings.

Timeline and Budget: The expansion was completed on schedule and within the allocated budget, demonstrating effective project management and execution.

Conclusion

The Coil Field Expansion project not only addressed the immediate need for increased storage but also set a new standard for operational efficiency and safety at BlueScope Steel Springhill Works. This project exemplifies our commitment to delivering solutions that offer both immediate benefits and long-term value to our clients.

Bluescope Steel Ammonia Still Redesign and Metric Conversion - Port Kembla Steel Works

Project Overview

DesignX Consulting was commissioned by BlueScope Steel to undertake a comprehensive redesign project for an existing ammonia still. This project involved converting the original imperial measurements to metric, replacing cast iron components with structural steel, and providing a full suite of engineering drawings for fabrication.

Project Scope

Documentation Review: Initial review of all existing drawings, both general arrangement and detailed, to understand the current design fully.

3D Modeling: Creation of a detailed 3D model of the existing ammonia still to serve as the foundation for redesign and modifications.

Unit Conversion: Conversion of all dimensions and specifications from imperial to metric system to align with modern standards and ease of manufacturing.

Material Conversion: Redesign of components originally made from cast iron to be constructed from structural steel, enhancing durability and ease of fabrication.

Client Collaboration: The 3D model was issued to BlueScope Steel for review, ensuring that all client specifications and requirements were met. Feedback was incorporated to finalize the model.

Engineering Drawings: Development of a complete fabrication drawing package, which included: General arrangement drawings, Detailed assembly drawings and Individual part and weldment drawings.

Conclusion

This project not only modernized the ammonia still design for BlueScope Steel but also improved its structural integrity by transitioning to structural steel components. The meticulous conversion process and detailed documentation provided by DesignX Consulting ensure that the new ammonia still meets current engineering standards, is easier to fabricate, and integrates seamlessly into BlueScope's coke making operations. This redesign enhances operational efficiency and aligns with global metric standards, facilitating easier maintenance and potential future modifications.

Bluescope Steel Recoiler Dummy Mandrel - Coupled Pickle Cold Mill (CPCM) Springhill Works

Project Overview

DesignX Consulting was engaged by BlueScope Steel to provide specialized engineering drafting services for the CPCM Carousel Recoiler Dummy Mandrel project. This initiative focused on developing detailed 3D models and 2D drawings to facilitate the manufacturing and machining of various replacement components for the mandrel assembly.

Project Scope

3D Modeling: Comprehensive 3D Inventor models were created for key components including the Main Segment, Sub Segment, Main Block Shoe, Sub Block Shoe, Main Segment Liner, Mandrel Retainer, Shifting Yoke, Mandrel Bush, Mandrel Cap, Wedge Rod, and Mandrel Shaft. These models included modifications for workshop setup and segment machining. An assembly model was developed incorporating all proprietary parts as specified in the original supplier drawings, ensuring accurate representation of the final assembly.

2D Drafting: Detailed 2D manufacturing drawings were produced for the modified Wedge Rod and Mandrel Shaft, providing clear instructions for machining. A comprehensive 2D assembly drawing of the Dummy Mandrel was created, complete with balloon callouts and a Bill of Materials (BOM) for all parts necessary for setup, aiding in the machining process.

Conclusion

This project not only enhanced the precision and efficiency of the manufacturing process for the CPCM Carousel Recoiler Dummy Mandrel but also allowed for accurate offsite manufacture and precise machining of mandrel segments, enabling the replacement of worn-out components on the in-service mandrel with minimal downtime.